Equipment introduction

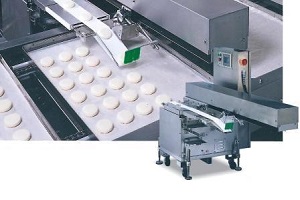

Shuttle Panner AP071, AP072

■Receive products formed by the encrusting machine and pan them in uniform rows.

The Shuttle Panner automates the labor-consuming operation of picking up and placing products onto trays.

This equipment is used in conjunction with any Rheon encrusting machine.

- Features

-

AP071 : Ability to pan long-formed products. Optional operation panel is available for independent operation of AP071.

AP072AP072 : While panning, the Shuttle Panner automatically compensates for uneven product distribution from the previous line, so that evenly spaced products are panned continuously.

AP072AP072 : While panning, the Shuttle Panner automatically compensates for uneven product distribution from the previous line, so that evenly spaced products are panned continuously.

The panner can store 10 different placement patterns in its memory. By recalling a product code, the panner can instantaneously equip itself to adapt to different products and product sizes.

The operation panel is a touch panel screen to ease delicate adjustments involving panning pitch, number, and position.

- Specifications

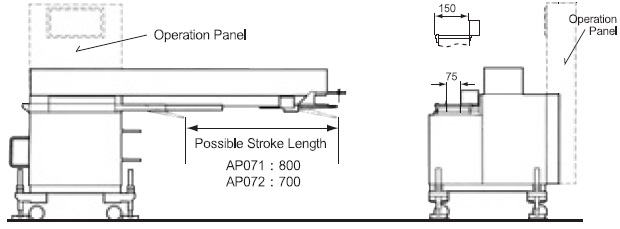

(The panning proceeds at a right angle from the encrusting machine's flow direction.)Machine Code AP071 AP072 Operation Panel Operation Panel is optional Operation Panel is standardized Possible Panning Number 1 - 15pcs. / row 3 - 15pcs. / row Possible Panning Range 800mm 700mm Possible Rate Product 60pcs/min.(max.) 20 - 60pcs/min. Minimum Pitch 30mm (between Products) (Same as on the left) Panning Pattern 6 x 5 panning, 7 x 5 panning, 8 x 6 panning etc. (Same as on the left) Height of the Belt Surface 610 - 870mm (Same as on the left) Belt Width 75mm (for 1 Encrusting Machine)

150mm (for 2 Encrusting Machines)(Same as on the left)

- Dimensions

Total Length 1650mm Total Width 680mm (765mm / Operation Panel Equipped) Total Height 792-1052mm (1133-1393mm / Operation Panel Equipped)